Компоненты дробилки

As the demand for minerals escalates, so does the need for environmentally responsible mining practices. Drilling machines today are designed with environmental sustainability in mind. Advances in technology have led to more efficient water usage, lower emissions, and reduced noise levels. Furthermore, many drilling operations now incorporate measures to minimize land disturbance and rehabilitate sites after drilling activities are completed.

3. Mud Pumps Drilling fluid, or mud, is essential for lubricating the drill bit, stabilizing the borehole, and transporting cuttings to the surface. Mud pumps are used to circulate this drilling fluid through the drill string and back to the surface. The efficacy of the mud system can significantly influence drilling efficiency and safety.

The 185 CFM diesel air compressor is versatile enough to serve numerous applications. Here are a few prominent ones

Advantages of Submarine Hammer Drilling

In conclusion, water well drilling, or forage, is not merely a technical operation; it is a crucial element in addressing the world's water challenges. By providing communities with direct access to groundwater, it supports health, agricultural productivity, and economic stability. As we face increasing pressure on our water resources, investing in modern, sustainable drilling practices will play a pivotal role in ensuring that future generations have access to the clean water they need to thrive. It is incumbent upon governments, organizations, and individuals alike to recognize the significance of this practice and to advocate for policies that enhance water security through responsible well drilling initiatives.

2. Jaw Plates

2). Features:

1, the drill selects the motor through the high-performance reducer as the reverse power; Use cylinders for propulsion. The hydraulic system is eliminated, so the mechanical efficiency is high, the cost is low, and the performance is stable.2, with anti-card maintenance, when the drill is stuck, the motor is not easy to burn, the reducer is not easy to damage.

3, simple and easy to move, the weight of the drill machine is less than 500Kg, and can be broken down into three pieces, easy to move and put on the shelf.

4, the selection of rolling drag plate, the track is not easy to wear.

5, the drilling machine uses semi-automatic cloud dynamic disassembling drill pipe, high efficiency.

2). Features:

1, the drill selects the motor through the high-performance reducer as the reverse power; Use cylinders for propulsion. The hydraulic system is eliminated, so the mechanical efficiency is high, the cost is low, and the performance is stable.2, with anti-card maintenance, when the drill is stuck, the motor is not easy to burn, the reducer is not easy to damage.

3, simple and easy to move, the weight of the drill machine is less than 500Kg, and can be broken down into three pieces, easy to move and put on the shelf.

4, the selection of rolling drag plate, the track is not easy to wear.

5, the drilling machine uses semi-automatic cloud dynamic disassembling drill pipe, high efficiency.

This process can take anywhere from 30 minutes to an hour, depending on the vehicle and the level of difficulty involved This process can take anywhere from 30 minutes to an hour, depending on the vehicle and the level of difficulty involved

This process can take anywhere from 30 minutes to an hour, depending on the vehicle and the level of difficulty involved This process can take anywhere from 30 minutes to an hour, depending on the vehicle and the level of difficulty involved

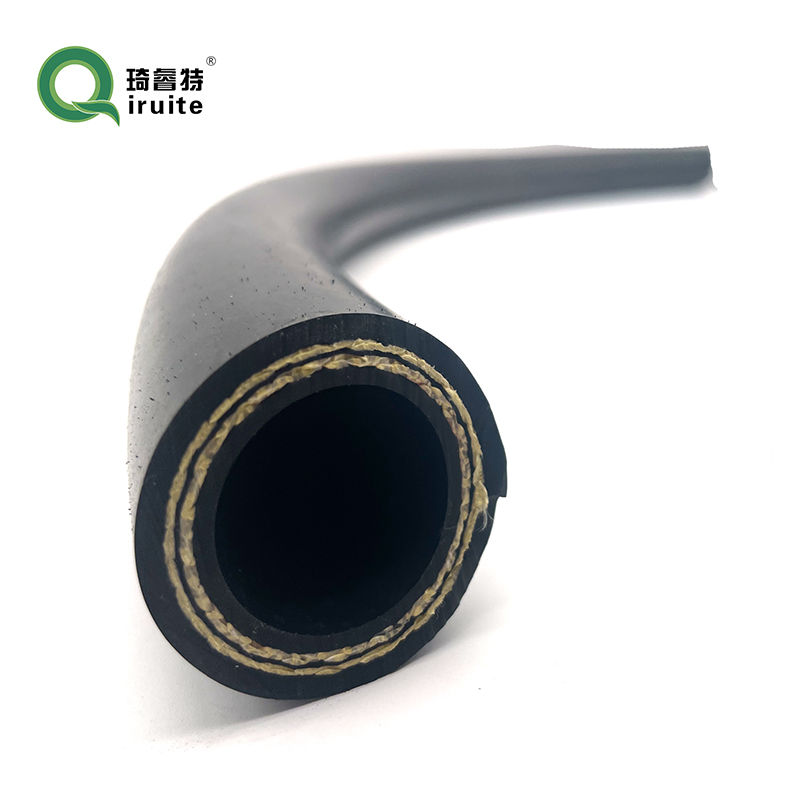

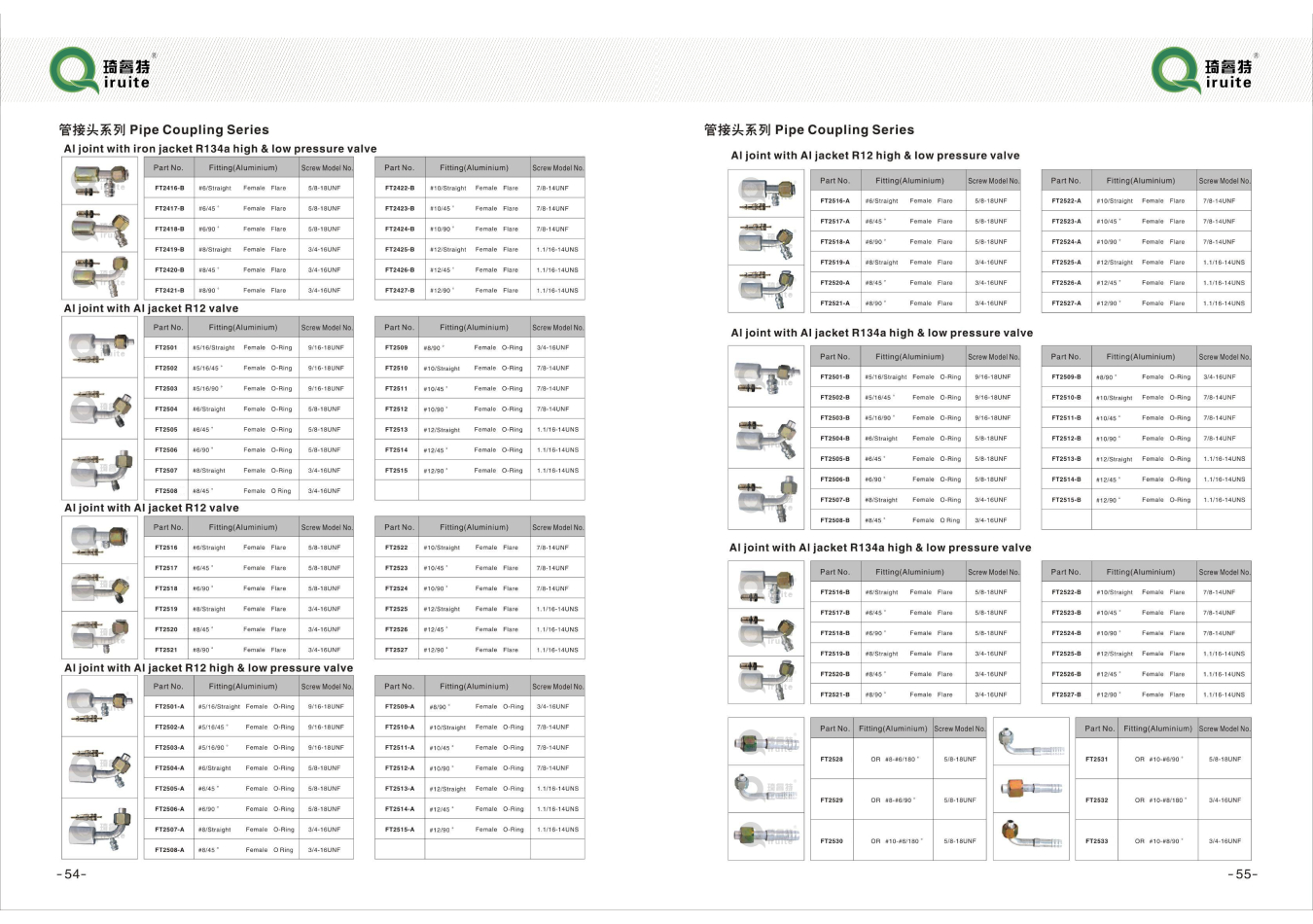

The coupling is made from durable materials such as stainless steel, brass, or galvanized steel, ensuring its longevity and resistance to corrosion The coupling is made from durable materials such as stainless steel, brass, or galvanized steel, ensuring its longevity and resistance to corrosion

The coupling is made from durable materials such as stainless steel, brass, or galvanized steel, ensuring its longevity and resistance to corrosion The coupling is made from durable materials such as stainless steel, brass, or galvanized steel, ensuring its longevity and resistance to corrosion